Introduction:

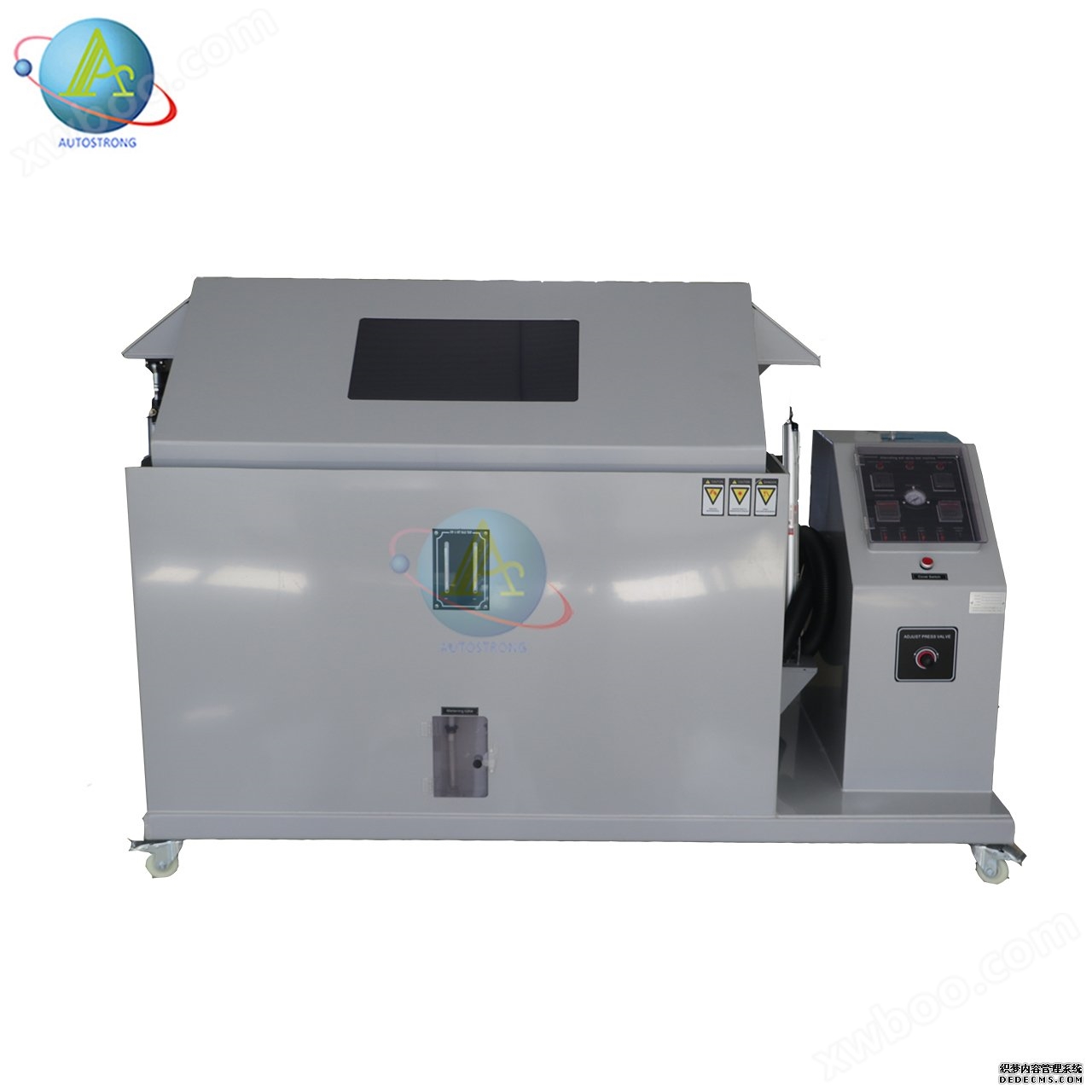

Walk-in Salt Spray Test Room is applied in the testing of surface treatment for large products from industries such as auto-making, national defense and military, solar-related products manufacturing and ship-building.

Conform to standard:

CNS: 3627, 3385, 4159, 7669, 8886; JIS: D0201, H8502, H8610, K5400, Z2371;

ISO: 3768, 3769, 3770; ASTM: 8117, B268

Technical Specification:

| Model | AUTO-WS8 | AUTO-WS12 | AUTO-WS16 |

| Inside capacity | 8 cubic meter | 12 cubic meter | 16 cubic meter |

| Workshop size (cm) | 200*200*200 | 300*200*200 | 400*200*200 |

| Lab temperature |

Saline testing method (NSS ACSS) 35°C± 1°C/Erosion -resistant testing method (CASS) 50°C ±±1°C. | ||

| Pressure pot | Saline testing method (NSS ACSS) 47°C ±1°C / Erosion-resistant | ||

| Temperature | Testing method (CASS) 63°C ±°C. | ||

| Saline temperature | 35°C±1°C ,50°C±1°C | ||

| Saline concentration | sodium chloride solution with 5% concentration or<0.26g 5="" copper="" chloride="" is="" added="" to="" each="" liter="" of="" sodium="" solution="" with=""> | ||

| Compressed air pressure | 1.00 ±0.01kgf/cm2 | ||

| Spray volume | 1.0~2.0ml/80cm2/h(at least collecting 16 hours and tade the average value) | ||

| Relative humidity in lab | above 85% | ||

| Value PH | 6.5-7.2 3.0-3.2 | ||

| Spray method | Continual spraying | ||

| Power | AC380V1 diameter 20A | AC380V1 diameter 30A | AC380V1 diameter 40A |

| Non standard type | Can be customized | ||

Fill out the form